Separation Internals

Separation internals are the engineered components inside process vessels that ensure efficient separation across gas–liquid, liquid–liquid, solid–liquid, and multiphase systems. Well-designed internals optimize flow, reduce pressure drop, and safeguard downstream equipment.

As a leading manufacturer and supplier of separation internals, Sepco Process delivers a complete portfolio of precision-engineered solutions- backed by 30+ years of hands-on engineering experience per project, rapid delivery, and local service from Conroe, TX, serving Houston and nearby regions.

Types of Separation Internals We Manufacture & Supply

We design, manufacture, and supply a full range of separation internals to meet diverse process conditions. Explore our sub-products below:

-

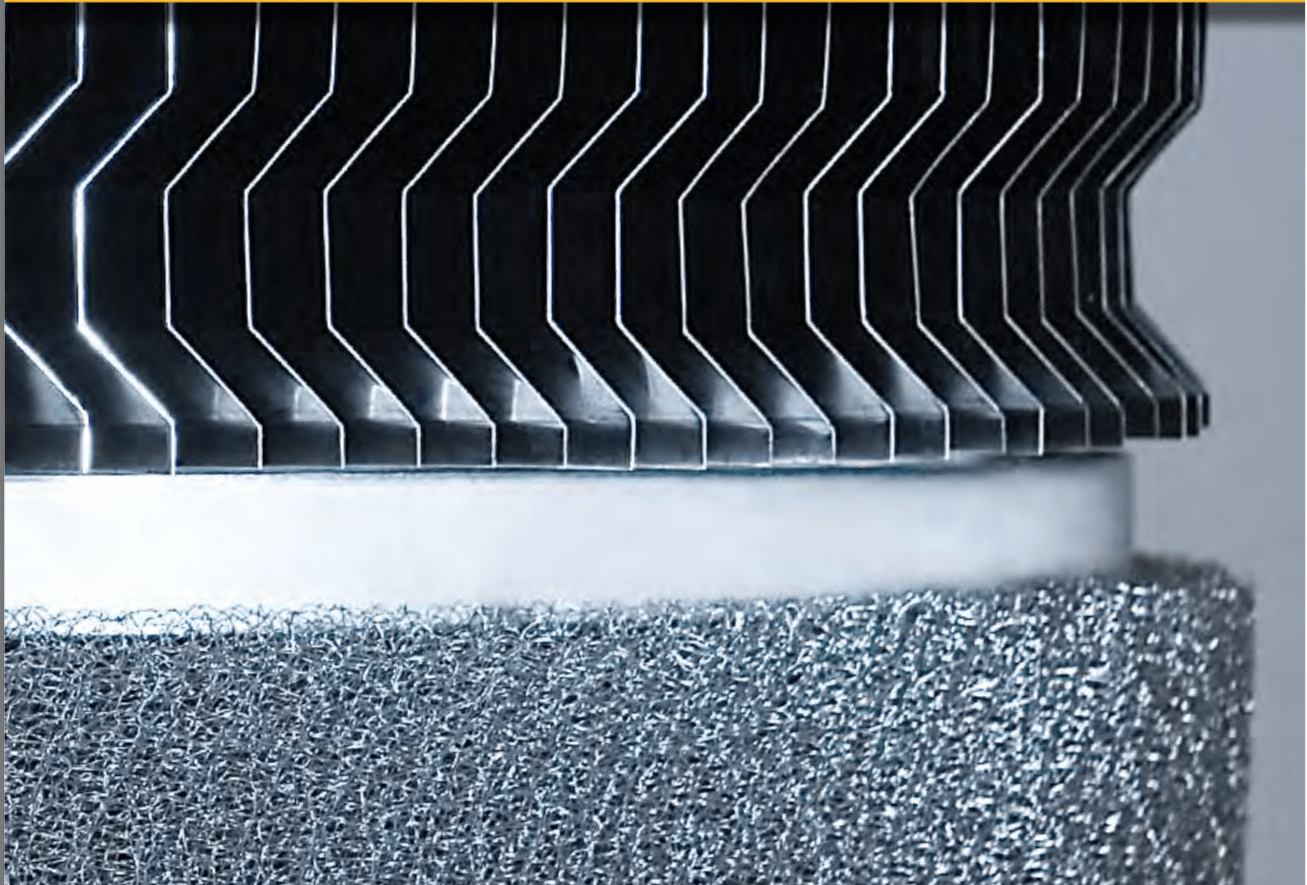

Mist Eliminators (Mesh Pads, Vanes, Axial Cyclones) – Remove liquid droplets from vapor streams to improve product quality and protect downstream equipment.

-

Multi Cyclone Separators – Compact, high-capacity units using centrifugal action for efficient gas–liquid or gas–solid separation.

-

Gas Filtration – Engineered filter solutions to remove particulates and contaminants, ensuring clean gas streams.

-

Coalescers – Enhance liquid–liquid separation by promoting droplet growth and efficient phase disengagement.

-

Liquid Filtration – Reliable removal of solids and contaminants from liquid streams to ensure product purity.

-

Feed Inlet Devices – Distribute multiphase streams evenly to reduce turbulence, improve separation efficiency, and protect internals.

-

Inlet Cyclones – Pre-separation technology that removes bulk liquid or solids at the inlet to reduce separator load.

-

Sand Removal Systems – Engineered for upstream oil & gas and water treatment applications, efficiently handling erosive solids.

-

Foam Breakers – Specialized internals designed to collapse foam layers, stabilizing separator performance.

-

Calming Baffles – Reduce turbulence, enhance liquid settling, and support efficient separation downstream.

Why Separation Internals Matter

Sepco Process manufactures and supplies separator internals that deliver measurable results:

-

Compact & High-Pressure Performance – Designs that reduce vessel size and weight while maintaining high efficiency, even under challenging pressure or turndown conditions.

-

Advanced Engineering & Modeling – CFD and 3D modeling optimize every internal, cutting CAPEX/OPEX and ensuring a fit-for-purpose design.

-

Retrofit & Revamp Expertise – Replacement of internals can revitalize existing vessels quickly, improving performance while avoiding full replacement. Our retrofit solutions minimize downtime and deliver measurable separation gains.

-

Improved Product Purity & Equipment Life – Cleaner feeds protect compressors, turbines, and heat exchangers from fouling and erosion.

Applications Across Industries

As trusted manufacturers and suppliers of separation internals, we support vital sectors such as:

-

Oil & Gas (Production & Refining)

-

Petrochemicals & Chemicals

-

Water & Environmental Systems

-

Power Generation

-

Food & Beverage

-

Pharmaceutical & Specialty Chemicals

The Sepco Process Advantage

-

Expert Engineering — 30+ years of separation-project experience per engineer

-

Speedy Delivery — Quotes in days, orders in weeks, outpacing many other suppliers

-

Precision Design — CFD, FEA, and prototype modeling for accuracy

-

Proven Retrofit Performance — Cost-effective separation upgrades for existing vessels

-

Local & Global Capability — Based in Conroe, serving Houston and beyond with world-class manufacturing and supply services

Ready to Elevate Your Separator Performance?

From mist eliminators to coalescers and multi-cyclone separators, Sepco Process is your trusted manufacturer and supplier of separation internals that excel in efficiency, compactness, and reliability.

Contact us today to learn how our advanced internals can optimize your system’s performance.