Vanes

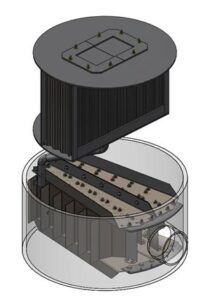

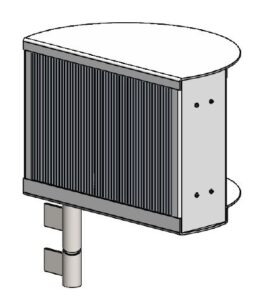

Vanes are the other most-used mist-eliminators that are made from the corrugated parallel sheets held at a fixed distance apart. This holding of the corrugated parallel sheets creates a tortuous flow path for the gases with mist. Sometimes, vanes are also called chevrons.

When flowing through the vane, a gas changes its direction of flow. This change in the direction of the flow of gases when passing through the vanes is called as ‘pass’. It’s all due to the inertia of the heavier liquid droplets that creates a contact between the liquid mixture and the surface of the vane. This is the very point of the mixture’s adherence and coalescence for the formation of a liquid film.

Vanes have the capacity to operate at higher gas velocities than other mist-eliminators like the mesh pads. There are modern multipocket vanes available in multiple models that can easily increase the capacity of an existing wheel.

At Sepco Process Inc., we make sure all our mist-eliminators; i.e., either mesh pads, vanes, or any other of its types; work the best by aiding liquid separation and retention at increased gas velocities. Thus, we employ some of the well-experienced and certified engineers at our company who are all dedicated to providing high-quality mixture separation equipment that can help in increasing the work efficiency of the mixture processing industries, mineral extraction industries, and other similar businesses.